Home Heat Treatment Services

Heat Treatment Services

Heat Treatment Services

We offer Pre- Heat during the welding and Post Weld Heat Treatment (PWHT) to improve weld microstructure and reduce residual stresses developed during welding.

Pre-Heat Treatment (PHT)

Preheating is a process that uses controlled heat during the welding of metals, with codes mandating that certain metals must be within a specific temperature range before welding can begin. The process of Pre-Weld Heat Treatment involves preheating each side of the weld joint to a predetermined temperature, achieved through the application of thermocouples, electrical resistance heating elements, or induction heating coils, and insulation placed around the welded area to maintain controlled preheat during welding.

This treatment helps reduce the cooling rate of the weld puddle/pool between each weld pass and drives out moisture in the parent metal, preventing hydrogen build-up and the potential for cracking during the welding phase. Maintaining the required preheat and interpass temperature (the maximum allowable temperature before a new weld pass may begin) is critical. This ensures the production of a softer, less brittle microstructure, allowing hydrogen to diffuse out of the weld metal and the heat-affected zone (HAZ) during welding.

Post-Weld Heat Treatment Service (PWHT)

Post Weld Heat Treatment (PWHT), commonly referred to as stress relieving, involves the application of controlled heat after welding is complete. During welding, the high temperatures and rapid cooldown create stresses in the molecular structure of the welded parts. PWHT helps mitigate these stresses by allowing the metallurgical structures and molecules of the weld and parent metal to blend together during the heat-up, soak period, and cool-down, resulting in a finished product that meets the intended design criteria. This process reduces or redistributes the residual stress introduced by welding through a technique that involves heating, soaking, and cooling the weldment or machined surface to controlled temperatures, thereby improving its properties. Other benefits of PWHT include improved ductility, reduced or improved hardness, reduced risk of brittle fracture, relaxed thermal stress, tempered metal, removal of diffusible hydrogen to prevent hydrogen-induced cracking, and improved metallurgical structure.

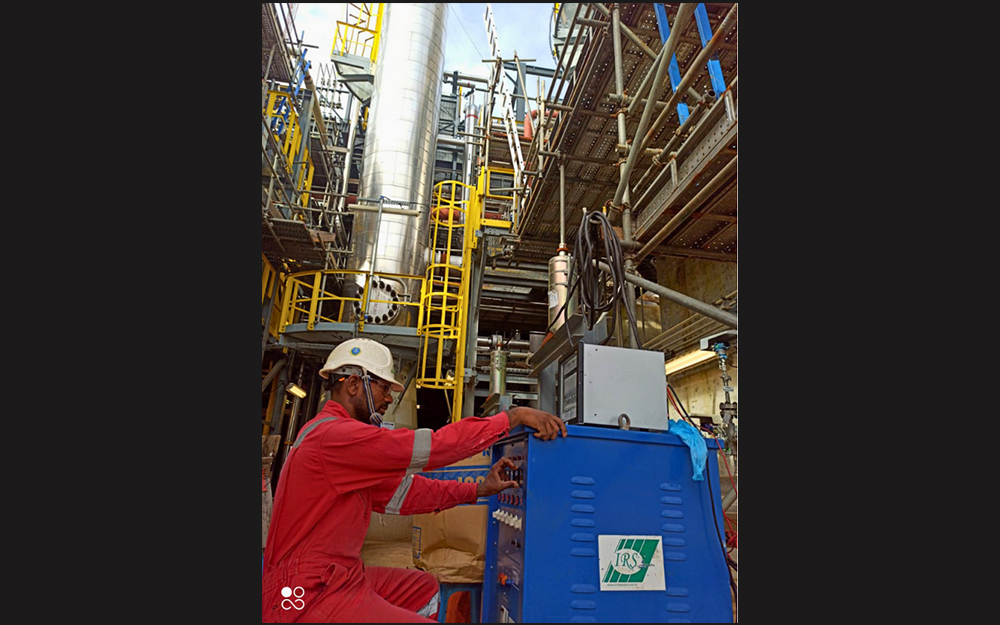

International Reliability Services Sdn Bhd (IRSSB) can perform PWHT at customers’ sites, both offshore and onshore, using portable equipment.