Advanced / Specialist Non-Destructive Testing

Remote Field Electromagnetic Testing (RFET)

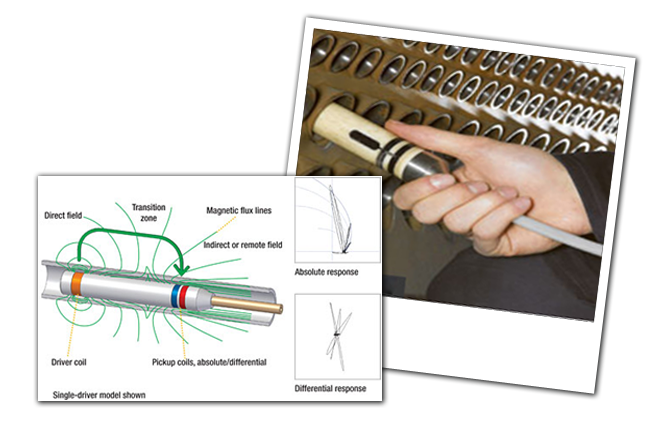

This is one of the most commonly used techniques for the inspection of ferromagnetic tubing. An exciter coil generates eddy currents which move through the thickness of the tube travel along the outside of the tube and are detected by a detector coil after again passing through the thickness of the tube. In the direct vicinity of the exciter coil The direct eddy current field predominates and to achieve a true remote field signal the coil spacing must be between 3 and 5 times the tube diameter.

In the past Remote Field Testing was commonly referred to as Remote Field Eddy Current. This has led to much confusion as it was often assumed to be similar to eddy current testing the only difference being that it was applied to ferromagnetic materials. In fact there is a big difference between the two techniques and lately the preference has been to use the term Remote Field Testing to clearly distinguish between the two techniques. As with conventional eddy current testing, Remote Field Testing can operate in the differential and absolute modes to detect localised and more generalised wastage.